Đăng nhập

DESCRIPTION OF PRODUCT

Ucrete MF40AS is used in the electronics industry to protect sensitive electronic devices and in explosion hazarded ar-eas.

It is dense and impervious, providing the ideal floor finish for applications in the electronics, food, pharmaceutical and manufacturing industries including clean room, labora-tory, packing hall and warehouse applications and wher-ever a robust, long lived floor is required.

Ucrete Industrial Flooring has been widely used throughout industry for more than 40 years; many of the older floors are still in service. A detailed project reference list is available upon request

PERFORMANCE DATA

ANTISTATIC PROPERTIES

Ucrete MF40AS meets the requirements of BS5958, EN1081, DIN51953 and EN61340.

For detailed information on earthing anti-static floors refer to the separate datasheet ‘Guidelines to Earthing of Ucrete antistatic floors’.

AIR QUALITY

Ucrete has been awarded the Indoor Air Comfort Gold La-bel following extensive VOC emission chamber testing and auditing of quality management and production control pro-cedures.

This demonstrates that Ucrete is an extremely clean prod-uct without any volatile compounds that might taint foodstuff or affect the well-being of personnel.

All Ucrete grades give very low emissions and conform to all the emissions requirements for indoor flooring systems in Europe including AgBB in Germany, Afsset in France, where they are rated A+ for VOC emissions (the cleanest rating), and M1 in Finland.

For further information please contact your local BASF representative.

TEMPERATURE RESISTANCE

A Ucrete MF40AS floor is fully resistant to liquid spillage and discharge up to 70°C. Suitable for freezer temperatures down to -15°C.

NON TAINTING

Ucrete MF40AS is non tainting from the end of mixing, as tested by the Campden Technology Ltd.

CHEMICAL RESISTANCE

Ucrete MF40AS offers exceptional resistance to a wide range of chemical aggressors. For example Ucrete is re-sistant to spillages of the following commonly encountered classes of chemicals:

Most dilute and concentrated organic acids such as, Acetic Acid, Lactic Acid, Oleic Acid and Citric Acid as commonly found in the food industry,

Dilute and concentrated acids: hydrochloric, nitric, phos-phoric and sulphuric.

Dilute and concentrated alkalis, including sodium hydroxide to 50% concentration

Animal fats and vegetable oils, sugars flavourings and essences.

Mineral oils, kerosene, gasoline and brake fluids

A wide range of organic solvents including Methanol, Xylene Ethers and Chlorinated solvents

Note: some staining or discolouration may occur with some chemicals, depending upon the nature of the spillage and the standards of housekeeping employed.

Extensive chemical resistance tables are available in the separate data sheet ‘A guide to the chemical resistance of Ucrete Flooring’.

For detailed information, please contact your local BASF Construction Chemicals office for guidance.

IMPACT RESISTANCE

With high mechanical strengths and a low elastic modulus, Ucrete MF40AS is very resilient and able to withstand se-vere impact loads. While no material is indestructible and surface chipping may occur, brittle modes of failure result-ing in cracking and disbondment are unknown with Ucrete floors.

Density 1970 kg/m³

Compressive strength (EN13892-2) 48 - 53 MPa

Tensile strength (BS6319 Part 7) 7 - 9 MPa

Flexural strength (EN13892-2) 18 - 21 MPa

Compressive modulus (BS 6319:Part 6) 3250 - 4000 MPa

Adhesive strength to concrete (EN13892-8) concrete failure

Coefficient of thermal expansion(ASTM C531:Part 4.05) 3.6 x 10-5 ºC-¹

Fire Testing (EN13501: Part 1) BFL – S1

Resistance to earth (EN1081) < 1 MΩ

Resistance to earth (EN61340-4-1) < 1 GΩ

Resistance of man to earth (EN61340-4-5) < 35 MΩ

Body voltage generation (EN61340-4-5) <100 V

SUBSTRATE MOISTURE TOLERANCE

Ucrete Industrial Flooring is extremely tolerant to residual substrate moisture and can be installed directly onto 7 day old concrete, or onto old good quality concretes with high moisture contents without the use of special primers, pro-vided there is a functioning DPM within the structure.

This enables rapid construction programmes to be main-tained and facilitates refurbishment work in wet process ar-eas.

Epoxy surface DPMs should not be used as they soften un-der high temperature conditions and will lead to floor failure.

PERMEABILITY

Ucrete MF40AS exhibits zero absorption when tested to CP.BM2/67/2.

CLEANING & HYGIENE

Regular cleaning and maintenance will enhance the life and appearance of any floor. Ucrete MF40AS is readily cleaned with industry standard cleaning chemicals and equipment. Please consult your local cleaning chemical or equipment supplier.

Detailed cleaning guidelines are available from your local BASF Construction Chemicals office.

SLIP RESISTANCE

The Ucrete MF40AS floors have coefficient of friction as de-termined to EN13036 Part 4 with 4S rubber on the wet floor as follows:

Ucrete MF40AS 30 - 35

The UcreteMF40AS surface profiles conform to DIN51130 as follows:

UcreteMF40AS R10 V -

Optimum slip resistance can only be maintained with regu-lar cleaning.

COLOURS

Ucrete MF40AS is available in eight standard colours:

Red -Yellow- Green- Orange

Grey- Blue -Green/Brown- Cream

Ucrete floor systems have been formulated to provide the very highest chemical and heat resistance. As a direct re-sult, some yellowing of the installed floor will occur in areas of direct UV exposure. This is most apparent in lighter col- ours.

SPECIFICATION

The floor finish shall be Ucrete MF40AS from BASF plc, Construction Chemicals of 19 Broad Ground Road, Red-ditch, Worcestershire, B98 8YP, installed at 4/6*mm in ac-cordance with the manufacturer’s instructions.

*(select as required)

SUBSTRATE QUALITY

Concrete substrates should be visibly dry and have a mini-mum tensile strength of 1.5 MPa.

Refer to the guide ‘The Design & Preparation of Substrates for Ucrete Industrial Flooring’

All joints in the substrate concrete subject to movement should be reflected through the Ucrete floor and sealed with a suitable sealant.

APPLICATION CONDITIONS

For best results materials, substrate and air temperature should be in the range 18 - 22ºC. Whilst Ucrete MF40AS will cure out effectively over a wide range of temperatures the optimum appearance is most readily achieved under good site conditions

Low temperatures will retard the setting and can impair the visual appearance of the floor.

High temperatures will shorten the open time and can im-pair the appearance of the floor.

COVERAGE

4mm: 8 - 10kg/m2

6mm: 12 - 14kg/m2

CURING

Normally Ucrete MF40AS can be put into service within 24 hours.

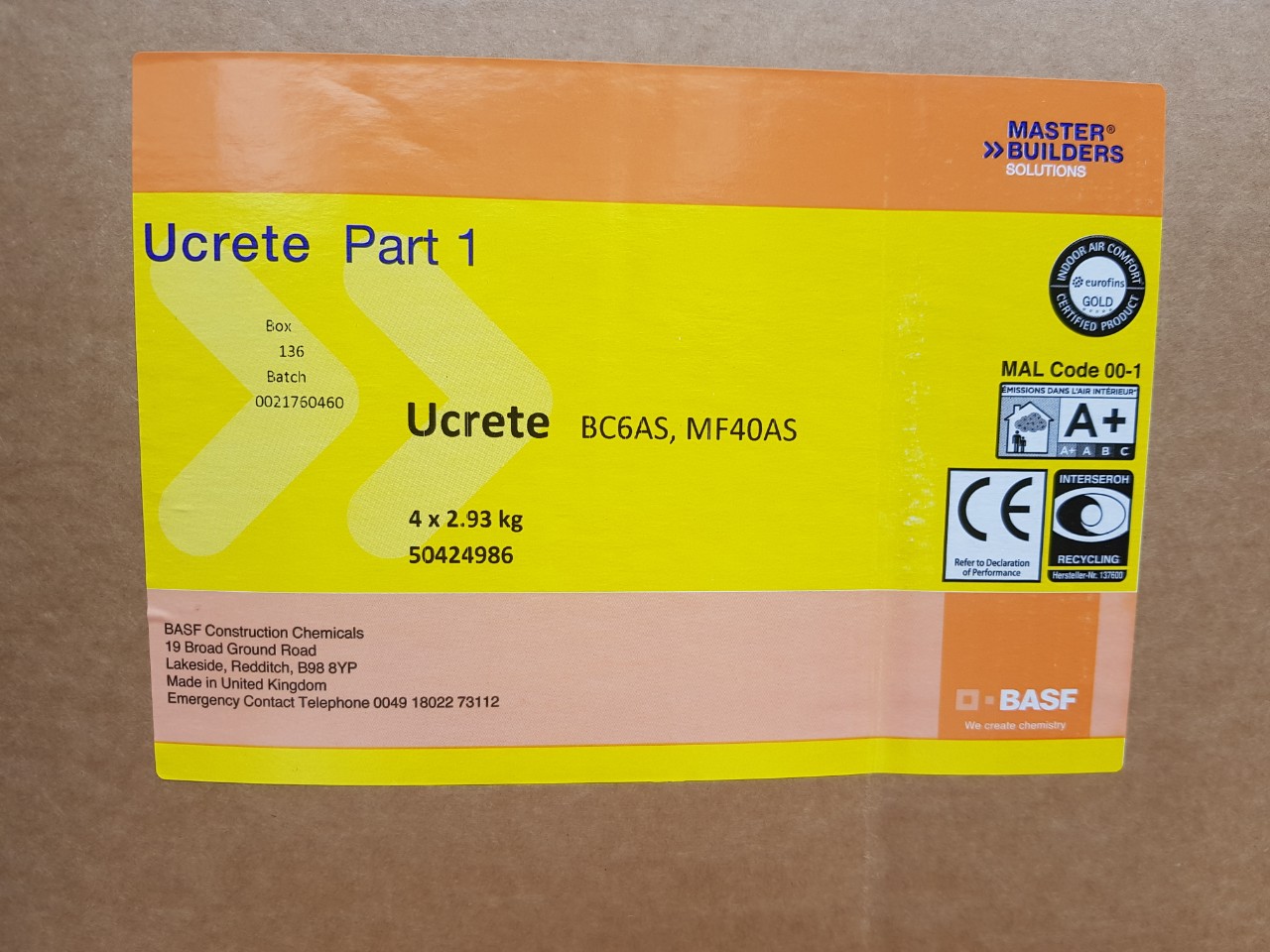

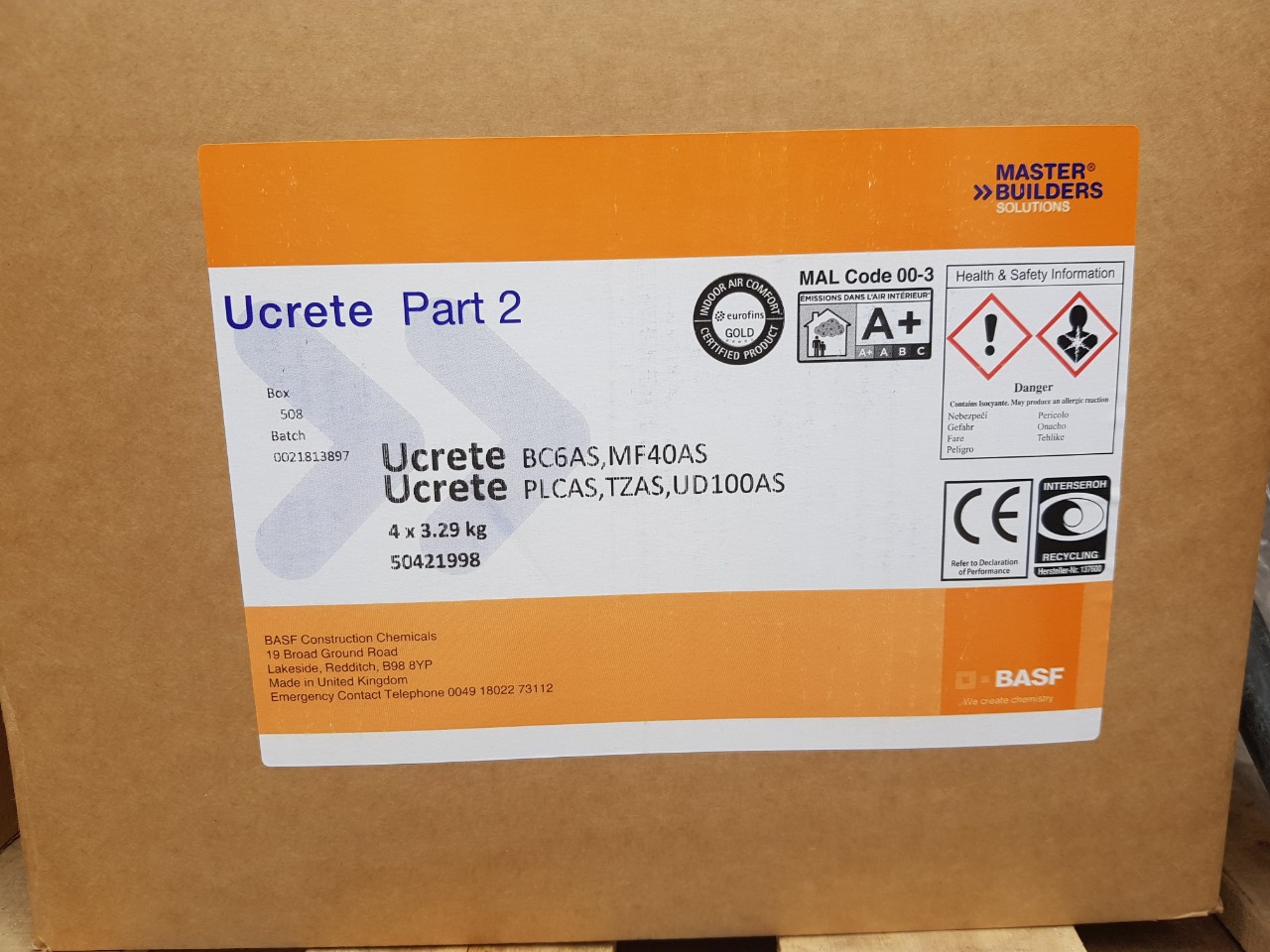

STORAGE

In covered warehouse conditions, above 5ºC and below 30ºC and out of direct sunlight. Materials must be raised off the floor and kept dry. Liquid components must be pro-tected from frost.

DISPOSAL

Part 2 containers should be decontaminated with 5% so-dium carbonate (washing soda) solution after use and dis-posed of as building waste in accordance with local regula-tions.

WARNINGS AND PRECAUTIONS

In its cured state Ucrete is physiologically non-hazardous.

For normal flooring applications Ucrete does not require the use of respiratory protective equipment during installation.

Operatives should consult the CoSHH risk assessment and their work instructions.

Sản phẩm liên quan

UCRETE MF40AS

THÔNG TIN KHÁCH HÀNG

ĐỊA CHỈ GIAO HÀNG

HÌNH THỨC THANH TOÁN

UCRETE MF40AS

THÔNG TIN KHÁCH HÀNG

- Họ và tên:

- Điện thoại:

- Email:

ĐỊA CHỈ GIAO HÀNG

- Địa chỉ:

- Quận / huyện:

- Tỉnh / thành phố:

- Phí vận chuyển:

- Ghi chú:

HÌNH THỨC THANH TOÁN